Air Compressors Sales & Service in Sydney | Fracks Pty Ltd

Looking for a wide range of air compressors, dryers or filtration products in Sydney? Call the experts at Fracks Pty Ltd now on 02 9211 1163.

Rotary Screw Compressors

Optimum Energy Efficiency

- signed its SM series compressors with optimum energy efficiency in mind.

- SM models all share logical and user-friendly design throughout. For example, the left-hand side panel can be removed in a few simple steps to allow excellent visibility of the system’s intelligently laid out components.

- SM series compressors are impressively compact, which makes them the perfect choice for applications where space is at a premium.

- AIRCENTER versions which, in addition to a refrigeration dryer, feature an air receiver installed underneath.

- The SM 13 model is also available with a frequency converter for infinitely variable flow rate control.

- At the heart of every SM system lies a new, premium quality air end featuring Kaeser’s energy-saving SIGMA PROFILE rotors. With optimised flow characteristics, these rotors play a key role in setting new standards in specific power performance.

- The SIGMA CONTROL 2 ensures efficient control and system monitoring. The large display and RFID reader provide effective communication and maximum security.

- KAESER remains the only compressed air systems provider to equip compressors with Super Premium Efficiency IE4 drive motors as standard (SM 13 models), thereby delivering maximum performance and energy efficiency.

- KAESER’s innovative cooling system uses a highly efficient, dual-flow fan and separate airflow channels for cooling the motor, fluid / compressed air aftercooler and control cabinet.

Oil Lubricated Piston Compressors

High Grade Lubricating Fluid

- These compact Every KAESER trades compressor is filled with special high-grade lubricating fluid that virtually eliminates build up of oil-carbon deposits on the valves.

- In addition, the fluid enables the lubrication change interval to be doubled to approximately 1000 operating hours.

Stainless Steel Valves

- The valve reeds in the corrosion-resistant stainless steel valves are fitted with heat-dissipating lift limiters to ensure airtight valve closure and extended service life.

Precision Machining

- Using the most advanced manufacturing processes and with more than 80 years of experience in precision engineering, KAESER’s skill and expertise guarantees products of the very highest quality standards.

- KAESER PREMIUM compressors are quality products Made in Germany. The LwA and CE symbols guarantee that all compressors conform to legal requirements.

- With their compact design, PREMIUM CAR trades compressors are convenient and efficient work companions. Not only stable and secure to safeguard against tipping over, they are also equipped with two sturdy wheels to allow easy transportation on the construction site.

- PREMIUM trades compressors are exceptionally versatile and are ideally suited for use in the demanding field of automotive repair. Whether carrying out rapid tyre changes, repairing minor bodywork damage or supplying compressed air to small workshops, a PREMIUM compressor from KAESER is the perfect choice.

Made from premium-grade materials

- Made from premium-grade materials and subjected to rigorous inspection, each KAESER KOMPRESSOREN compressor block is meticulously machined and assembled to ensure outstanding compressed air performance, efficiency and durability.

Refrigerated Air Dryers

Compressed air contains water vapor and as it travels through compressed air piping, it cools and the vapor condenses into liquid condensate. This condensate increases maintenance requirements and affects product quality. Fracks offers a wide range of efficient compressed air dryers for your compressed air system.

Choose the right compressed air dryer for your application from the list of options below, which includes:

Refrigerated Air Dryers

- Refrigerated dryers serve most compressed air applications. We have a wide range of refrigerated air dryers from 10 to 12,500 scfm for a variety of applications. All Kaeser dryers use refrigerants friendly to the environment.

Desiccant Air Dryers

- Desiccant dryers provide extremely dry air for processes that are very sensitive to moisture or applications where the air system is exposed to very low ambient temperatures. Dew points may be as low as -100°F. The desiccant material adsorbs moisture in the compressed air until it reaches its maximum capacity, at which point it must be regenerated. The method of regeneration is what differentiates the types of desiccant dryers (KAD, KED, DCF-HF, and KBD).

Membrane Dryers

- Our membrane dryers provide a simple and reliable way to dry compressed air to dew points as low as -40°F and reduce maintenance costs.

Compressed Air Filtration

Optimum Flow Distribution

- The element head of KAESER FILTER units is optimised for best possible air flow.

Tapered Internal Channels

- Kaeser screw compressors Tapered internal structure channels the compressed air towards the centre of the element interior for even charging of the filter media.

Minimal Pressure Loss

- The efficiency of a compressed air filter depends most of all on pressure loss.

High Performance Filters

- KAESER FILTER products feature generously-sized housings and filter surfaces, innovative flow dynamics and high-performance filter media.

High Efficiency Carbon Matting

- Unlike conventional filters, KAESER activated carbon filters with high-efficiency carbon matting prevent channelling whilst also ensuring reduced differential pressure.

- KAESER Filter matting provides highly effective protection against particle release.

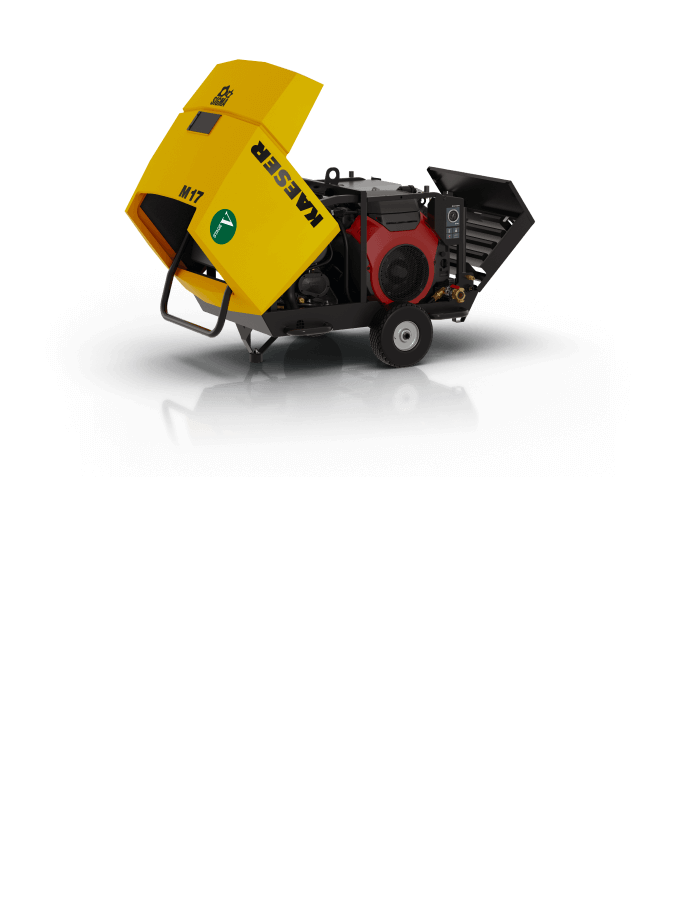

Mobile Portable Air Compressors

Easy to Transport

- These compact compressors are able fit into the tightest of loading spaces, which leaves the vehicle towing hitch free for use.

Easy to Load

- The compressor can be manually lifted via four ergonomically designed hand grips to enable easy loading into a van.

High Performance

- The impressive performance and staying power of petrol-powered models is made possible thanks to the generously sized fuel tank and continuous flow rate control, which precisely matches air flow to meet actual demand. This further reduces the fuel consumption of these already efficient machines.

Easy to Read

- Easy-to read control panel with pressure gauge, operating hours counter and airend temperature monitoring.

- Straightforward key start-up and dependable cold-start with choke and electric starter for petrol engine models

- The frames are equipped with fixed connections for compressed air, fan power supply and condensate return. All you need you to do is connect the suitably equipped compressor.

- Suitable for use in ambient temperatures up to +40 °C, they deliver the energy required to power breakers, air spades, pneumatic drills, saws, wrenches, grinders, impact borers and pipe inspection robots.

- An external compressed air aftercooler can also be optionally connected to ensure a dependable supply of cool, condensate-free air at all times. If technically oil-free compressed air is required, an external filter combination can also be connected.

Oil Free Compressors

Quiet

- The i.Comp 9 is incredibly quiet, thanks to its exceptionally smooth-running compressor and sound-insulating PE enclosure.

Clean

- The i.Comp 9 compressor block contains no oil. i.Comp TOWER T versions deliver a constant supply of dry compressed air at a pressure dew point of +3°C.

Power

- The i.Comp 9 is a true endurance runner. Even 100% duty cycles at ambient temperatures as high as +45°C are just a walk in the park.

Endurance

- The i.Comp 9 is a true endurance runner. Even 100% duty cycles at ambient temperatures as high as +45°C are just a walk in the park.

Energy Efficient

- The i.Comp 9 is highly efficient in all load phases. Significantly reduced switching operations minimise energy losses and relieve pressure on the compressed air lines.

Reliable

- Reliable moisture protection for your work, equipment and instruments.

- The compressor keeps working reliably even when temperatures in your compressor room are high.

- Automatic, strain-relieved condensate line keeps maintenance to a minimum.

- SAM 4.0 Computer can be used as a remote control system

Air Receivers

High Quality

- An air receiver, sometimes referred to as a compressed air tank, is an integral part of any compressed air system.

- The main purpose of this is to act as temporary storage to accommodate the peaks of demand from your system and to optimize the running efficiency of your plant.

Compressed Air Accessories

Large Range

- We stock a full range of compressed air high flow, quick connect valves, including Oetiker, Nitto, Ryco, Jamec. You name it we have it.

- Compressed air tools, blow guns and spray equipment.

Contact Us Now

Contact Fracks for your compressed air needs simply by filling out the Contact Form or by calling.

Our experienced team is here to help you.

Compressor Sales, Service & Hire.

T: 02 9211 3364

M: 0418 235 765

E: [email protected]

A: 8-10 Whiting St, Artarmon NSW 2064